EMINENCE ENGINEERING

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to EMINENCE ENGINEERING

Under Water Conveyors

A wide choice of options allow Under water conveyors to be customized to suit specific application needs. This Submersible Conveyor, used in conjunction with a robot, has an elevated floor stand that raises it to meet the robot release height. Heavy duty castors allow it to be moved easily within the plant.

Telescopic Conveyor

Telescopic Conveyor is the perfect labor-saving component to meet the demands of high-speed production lines in a wide range of industries for raw material unloading and finished goods loading in the carriage.

Telescopic Conveyor is deluxe product for Loading/Unloading application with all necessary safety standards. Telescopic Conveyorhas heavy-duty design and durable construction requires minimal maintenance, thus assuring many years of dependable operation.Machine is having a very robust and vibration free body constructed on steel frame. It can also made with all food grade standards. User friendly and variable speed controls for conveyor speed make the operation easy to adjust as per output.

Vertical Coneyor

Vertical Conveyor is compact, simple and reliable, allowing companies to maximize their production efficiency without sacrifices.

Rugged Construction: features a robust formed steel channel construction to ensure stability of the structure and long operating life of components. Heavy-duty roller chain is combined with unique zero-backflex attachments to eliminate platform sag.

Flexible Throughput: It is designed to handle production rates up to 30 products per minute. Standard inverter duty motors allow to be synchronized with adjacent conveyors and equipment to adapt to changing production conditions and provide maximum throughput.

Accumulation Conveyor

Accumulation Conveyor are used for easy and fast feeding of bottles or other similar containers to a filling, labeling or other line. Accumulation Conveyor act as a buffer at the end of a line to enable bottles or similar containers to easily be handpicked for case packing for instance.

Close the gaps during accumulation mode, therefore allowing increased storage onto the conveyor. Advanced designs accumulate with diverters at the infeed to send onto the alpine and when unloading, providing merge systems the ability to handle a wide variety of product.

Side Grip Coneyor

The purpose of our Side Grip Conveyor is to provide a conveyor line a place to clear out down or broken product and loose debris from the conveyor chain. A common application is to use the over-the-end transfer on a glass line downstream of a bottle squeezer. Good bottles pass through the squeezer and are carried across the gap, while defective bottles shatter and the broken glass goes over the end of the conveyor and into cullet conveyor for recycling. The Side Grip Over-the-End Transfer features the same on-the-fly adjustment featured on our other Side Grip units to allow for different product widths. We will build the unit with as wide a gap as you want between the infeed and discharge conveyors, allowing us to accommodate a wide range of product heights.

Plastic Modular Belt Conveyor

Eminence manufactures innovative high performance and energy efficient modular plastic belt conveyor systems. Our low cost conveyor design combines direct drive motors and proprietary ultra-low friction plastic chain belting in a lightweight modular aluminum sectioned frame.

The modular conveyor belting simplifies construction and allows us to build any size belt with the same components. The conveyor belt has a smooth surface that improves corner turning while reducing scuffing when sliding under items.

Wire Mesh Conveyor

Wire Mesh Conveyor and chain driven conveyor belts are used worldwide in industries such as heat treating, forging, foundry, food processing, snack food, baking, ceramics, glass, automotive and more.

Eminence make Wire Mesh Conveyor is tight wire mesh for flexibility and conveying small parts, special smooth surface belts for easy accurate transfer, wire belts with large openings for easy flow of air or water and for simplified cleaning of your product.

Drive Roller Conveyor

Roller conveyor is suitable for all types of cartons, bags, salvers cargoes’ conveying. It can transport single heavy thing, or can bear more impact load. It has big throughput, high speed, light operation, and let multispecies of shunt delivery from collineation come true. Drive Roller Conveyort can be used in complex logistics conveying system which consists of multiple roller conveyors and other conveyors to reach various craft needs and accumulated conveying of material. Roller conveyor has simple structure, high reliability, and simple maintenance.

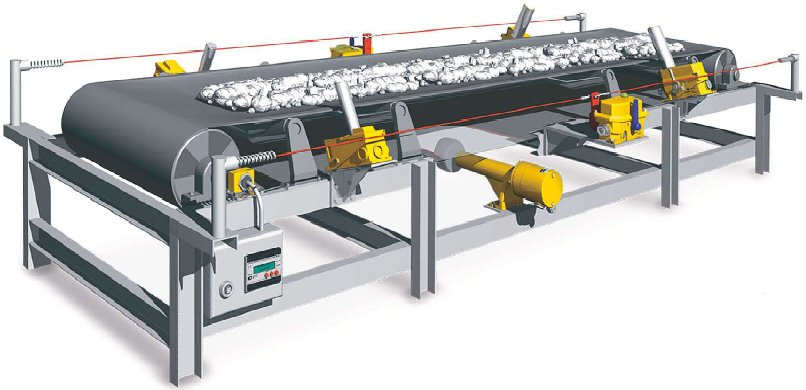

Rubber Belt Conveyor

Belt conveyors have many advantages over other types of bulk material handling equipment. Some of the advantages are:

Belt conveyors are capable of handling a wide range of bulk materials from very fine to large lump sizes. Very fine materials such as portland cement are loaded at terminals using belt conveyors. Large lump size materials such as coal are transported from mines using belt conveyors.

Belt conveyors can be designed to handle capacities for any operation. It is common for belt conveyors to unload ships at capacities up to 10,000 tons per hour. Belt conveyors can also be designed for batching operations or to convey a small amount of material between processes.

Belt conveyors can be configured to fit almost any application. A belt conveyor can convey material horizontally, on an incline or a combination of both. It is common to use a single belt conveyor to transport material horizontally a certain distance, then elevate the material on an inclined section of belt conveyor and then horizontally again.

Belt conveyors can be used to stock-pile or reclaim bulk materials. Radial stackers are used for creating large piles of materials such as wood chips, coal or ore. Reclaim belt conveyors are located under the piles to carry the materials into the plant for processing.

Belt conveyors require less horsepower to operate than other types of conveyors. Bulk materials are carried on top of the belt and remain static, therefore requiring much less energy to move.

Belt conveyors have proven to be a reliable method of conveying bulk materials.

Gravity Skatwheel Conveyor

A gravity conveyor moves the load without utilizing motor power sources, usually down an incline or through a person pushing the load along a flat conveyor. A gravity conveyor can utilize skatewheels or full rollers.

Skatewheel Conveyoris made with steel skatewheels mounted on axles to convey product. This is the most economical type of conveyor. It is frequently used for loading trucks with the conveyor set up on removable stands or supports. Skatewheel conveyors are good for items with a smooth, flat bottom. Unlike power conveyor, the load can be wider than your conveyor if centered correctly. Skate wheel conveyors flow better than roller conveyor. A minimum of ten wheels should be positioned beneath your load at any given time.

Gravity Roller Conveyor

Items with irregular surfaces, such as drums or older cartons and boxes, or items too loosely bagged to transport well on gravity wheel conveyors, can all be transported on the gravity roller conveyor.

Gravity roller conveyors use the same principles as wheel conveyor, but have some added advantages. They are available in light to medium duty construction and can therefore handle a wider variety of loads and be used in more robust applications.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.